- Basic objective of modular arm pole is to eliminate working at height and improve safety of maintenance crew.

- Modular arm pole is designed for easy maintenance.

- Used material for Modular arm pole is gear and pully with rope for moving pole bracket up and down.

- Modular arm pole is designed with clockwise rotation for UP and anti-clockwise for DOWN movement.

- Easy replacement of light fixture build in the safe way.

- It can replac existing Light Pole without making foundation changes.

- Motor driven option available on demand.

- It saves more than 70% maintenance cost and ROI is expected 3 years to almost free.

Highlights

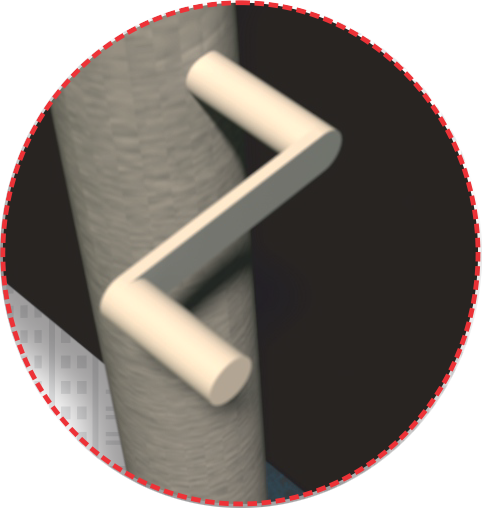

Handle

for Rotation

Movement

Of Bracket

Locking Point

Of Bracket In Pole

ProperAngle

For Light Fixture

Key Features

Safety

- Elimination of Work @ Height high-risk activity during Installation, Maintenance, Testing and Rectification / Eliminate use of light fixture.

- Eliminate use of scaffold and working on scaffold at height.

- Minimize the High Risk exposure hours during and after installation.

- Smaller Field crew required during Maintenance work.

- Auto locking system to stop movement of bracket incase of rotating handle slippage.

- Double pole MCB for safe electrical connection with weatherproof junction box considering Electrical safety.

Time

- Effective time saving during maintenance.

- Saving of time for scaffold installation and dismantling.

- Reduction in high risk exposure hours.

- Smaller Field crew required during Maintenance work.

- Multiple light fixture installation work possible simultaneously.

Quality

- GI Pole for long lasting rust free usage.

- Factory inspection before dispatch of material to site.

- Providing quality for minimum maintenance.

- Easy to install and Maintain.

- Provided conduit inside to isolate cable from direct contact with pole body.

- Provided proper interlocking system on top of pole between bracket and pole.

- Provided waterproof JB (IP 65) with rated MCB for electrical connection.

Cost Effective

- Reduction in after installation maintenance cost.

- Permanent cost saving solution of scaffold transportation after installation.

- Saving of Man power utilization during and after installation work.

- Easy to plan periodic check up of each pole after installation.